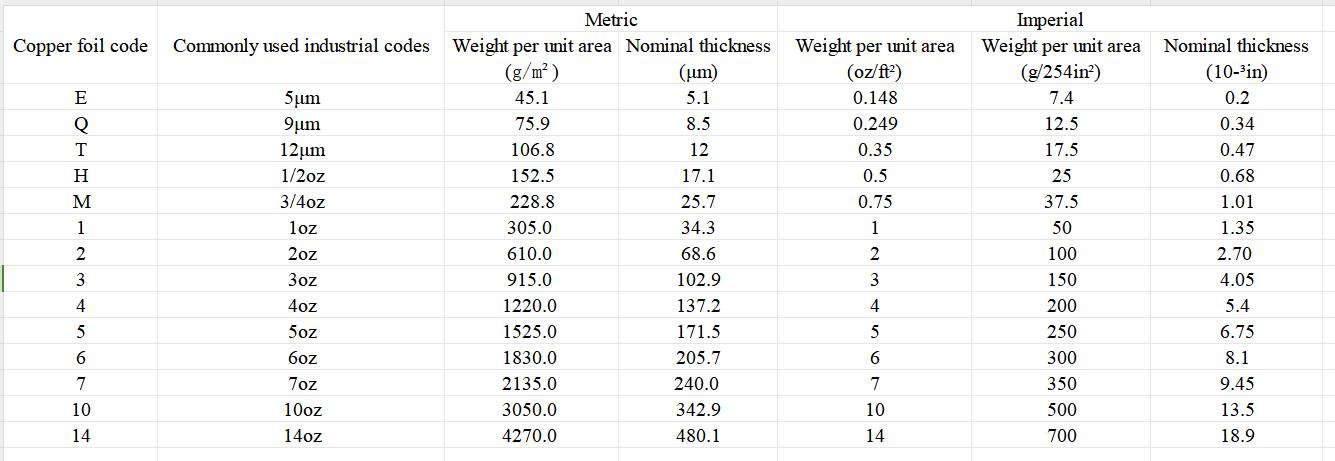

Kauri da nauyin jakar tagulla(An karbo daga IPC-4562A)

Kaurin tagulla na PCB mai sanye da tagulla ana bayyana shi a cikin oz na sarki (oz), 1oz=28.3g, kamar 1/2oz, 3/4oz, 1oz, 2oz. Misali, girman yanki na 1oz/ft² yayi daidai da 305 g/㎡ a cikin ma'auni. , wanda aka canza ta tagulla (8.93 g/cm²), daidai da kauri na 34.3um.

Ma'anar murfin jan karfe "1/1": foil na tagulla tare da yanki na ƙafar murabba'in 1 da nauyin 1 ounce; yada oza 1 na jan karfe a ko'ina a kan farantin karfe tare da yanki na ƙafa 1.

Kauri da nauyin jakar tagulla

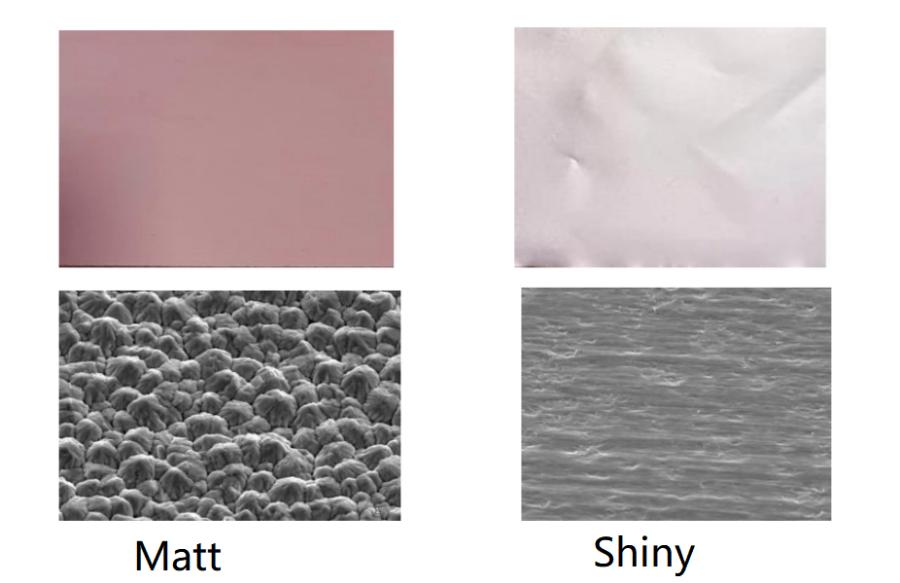

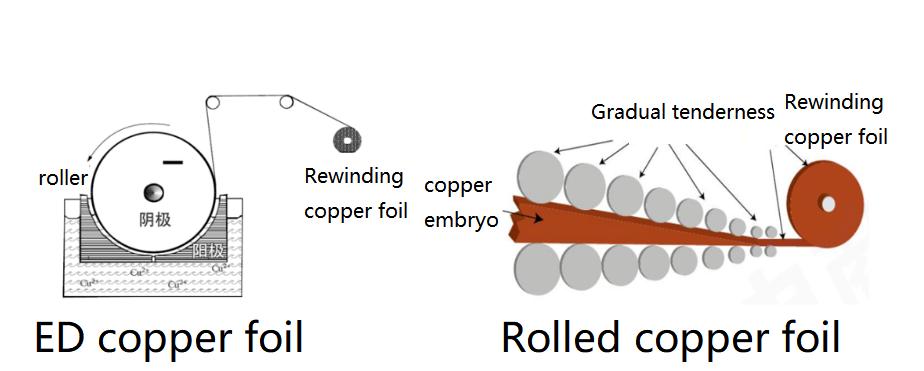

☞ED, Electrodeposited copper foil (ED copper foil), yana nufin foil na jan karfe da aka yi ta hanyar electrodeposition. Tsarin masana'antu shine tsarin lantarki. Kayan aikin Electrolysis gabaɗaya yana amfani da abin nadi na saman da aka yi da kayan titanium azaman abin nadi na cathode, ingantacciyar rarrabuwa mai ƙarfi mai ƙarfi ta tushen gami ko rufin da ba a iya narkewa na tushen lalata kamar anode, kuma ana ƙara sulfuric acid tsakanin cathode da anode. Copper electrolyte, ƙarƙashin aikin kai tsaye, yana da ions ƙarfe na jan karfe da aka tallata akan abin nadi na cathode don samar da foil na asali na electrolytic. Yayin da abin nadi na cathode ke ci gaba da juyawa, foil ɗin da aka ƙirƙira yana ci gaba da tallata shi kuma yana fitar da shi akan abin nadi. Sannan a wanke, a bushe, a raunata a cikin nadi na danyen foil. Tsaftataccen foil na jan karfe shine 99.8%.

☞RA, Rolled annealed copper foil, ana fitar da ita daga taman tagulla don samar da blister tagulla, ana narkar da ita, a sarrafa ta, ta hanyar electrolytically, sannan a sanya ta ta zama kauri kamar 2mm. Ana amfani da ingot na jan ƙarfe azaman kayan tushe, wanda aka tsince, raguwa, da zafi mai jujjuyawa kuma ana birgima (a cikin dogon lokaci) a yanayin zafi sama da 800 ° C sau da yawa. Tsafta 99.9%.

☞HTE, babban zafin jiki elongation electrodeposited jan foil, shi ne jan karfe tsare cewa kula da kyau elongation a high yanayin zafi (180°C). Daga cikin su, da elongation na jan karfe tsare da kauri na 35μm da 70μm a high zafin jiki (180 ℃) ya kamata a kiyaye a fiye da 30% na elongation a dakin da zazzabi. Har ila yau, ana kiransa HD bangon jan ƙarfe (high ductility copper foil).

☞DST, foil na jan karfe na gefe biyu na magani, yana roughens duka santsi da m saman. Babban manufar yanzu shine don rage farashi. Roughing da santsi surface iya ajiye jan karfe jiyya da browning matakai kafin lamination. Ana iya amfani da shi azaman rufin ciki na rufin jan ƙarfe don allunan Layer Layer, kuma baya buƙatar yin launin ruwan kasa (baƙar fata) kafin laminating allon multilayer. Rashin lahani shi ne cewa ba dole ba ne a tono saman jan karfe, kuma yana da wuya a cire idan akwai gurɓata. A halin yanzu, aikace-aikacen foil ɗin tagulla mai gefe biyu yana raguwa sannu a hankali.

☞UTF, ultra siriri jan ƙarfe, yana nufin foil ɗin tagulla mai kauri ƙasa da 12μm. Mafi yawan su ne foils na jan karfe da ke ƙasa da 9μm, waɗanda ake amfani da su akan allon da'ira da aka buga don kera kyawawan da'irori. Domin siraren jan karfe yana da wuyar iyawa, gabaɗaya mai ɗaukar kaya yana goyan bayansa. Nau'in masu ɗaukar kaya sun haɗa da foil jan ƙarfe, foil na aluminum, fim ɗin halitta, da sauransu.

| Lambar foil na Copper | Lambobin masana'antu da aka fi amfani da su | Ma'auni | Imperial | |||

| Nauyi kowane yanki na yanki (g/m²) | Kauri mara kyau (μm) | Nauyi kowane yanki na yanki (oz/ft²) | Nauyi kowane yanki na yanki (g/254in²) | Kauri mara kyau (10-³ in) | ||

| E | 5 μm | 45.1 | 5.1 | 0.148 | 7.4 | 0.2 |

| Q | 9m ku | 75.9 | 8.5 | 0.249 | 12.5 | 0.34 |

| T | 12 μm | 106.8 | 12 | 0.35 | 17.5 | 0.47 |

| H | 1/2oz | 152.5 | 17.1 | 0.5 | 25 | 0.68 |

| M | 3/4oz | 228.8 | 25.7 | 0.75 | 37.5 | 1.01 |

| 1 | 1 oz | 305.0 | 34.3 | 1 | 50 | 1.35 |

| 2 | 2oz ku | 610.0 | 68.6 | 2 | 100 | 2.70 |

| 3 | 3oz ku | 915.0 | 102.9 | 3 | 150 | 4.05 |

| 4 | 4oz ku | 1220.0 | 137.2 | 4 | 200 | 5.4 |

| 5 | 5oz ku | 1525.0 | 171.5 | 5 | 250 | 6.75 |

| 6 | 6oz ku | 1830.0 | 205.7 | 6 | 300 | 8.1 |

| 7 | 7oz ku | 2135.0 | 240.0 | 7 | 350 | 9.45 |

| 10 | 10oz | 3050.0 | 342.9 | 10 | 500 | 13.5 |

| 14 | 14oz | 4270.0 | 480.1 | 14 | 700 | 18.9 |