Tin na jan karfewani karfe ne mai rufin kwano a saman tulun tagulla. Tsarin samar da tsiri na jan ƙarfe na tinned ya kasu kashi uku: riga-kafi, tin plating da bayan jiyya.

Dangane da hanyoyin dasa gwangwani daban-daban, ana iya raba shi zuwa na'urar lantarki da kuma sanyawa mai zafi. Akwai bambance-bambance tsakanin igiyar jan karfen da aka yi da wutan lantarki da kuma tsomawa mai zafitinned jan karfe tsirita fuskoki da dama.

I. Tsarin tsari

1) Electroplating tinning: Yana amfani da ka'idar electrolysis don amfani datagulla tsirikamar yadda cathode da tin kamar anode. A cikin maganin electroplating mai dauke da ions tin, an rage ion tin a ajiye a saman ɗigon jan ƙarfe don samar da wani Layer da aka yi da tin ta hanyar aikin kai tsaye.

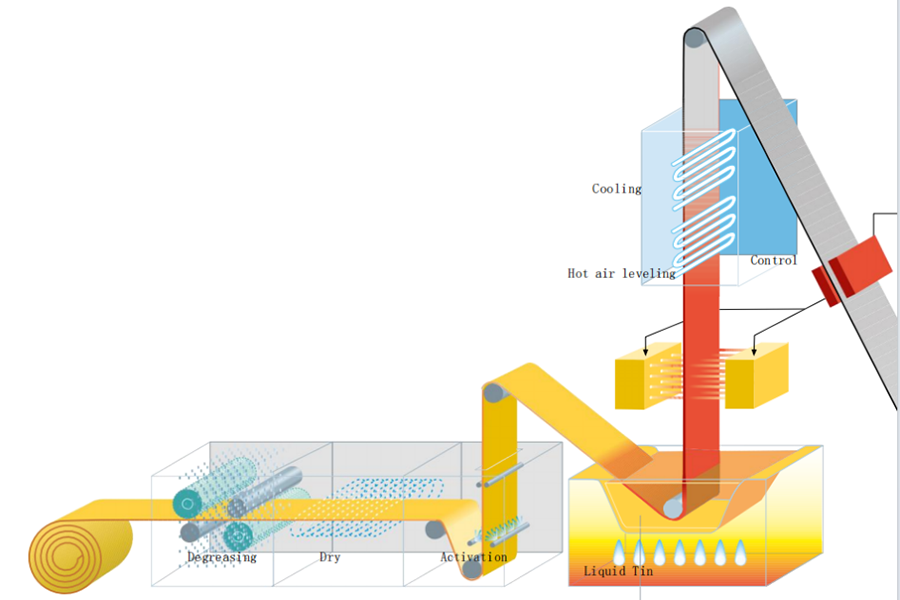

2) Hot-tsoma tinning: Shi ne don nutsad da datagulla tsiria cikin ruwa mai narkakkar ruwa. Karkashin wasu yanayin zafi da lokaci, ruwan gwangwani yana amsawa ta jiki da sinadarai tare da saman tsiri na jan karfe don samar da tin Layer a saman tudun tagulla.

II. Halayen sutura:

1) Rufe uniformity

A) Electroplating tinning: Rufe uniformity yana da kyau, kuma zai iya samar da uniform da m tinning Layer a saman natagulla tsiri. Musamman ga tubes na jan karfe tare da sifofi masu rikitarwa da saman da ba daidai ba, kuma yana iya rufewa da kyau, wanda ya dace da yanayin aikace-aikacen tare da manyan buƙatu don ɗaukar daidaituwa.

B) Hot-tsoma tinning: The shafi uniformity ne in mun gwada da matalauta, da m shafi kauri na iya faruwa a sasanninta da gefuna natagulla tsiri. Koyaya, don wasu lokatai waɗanda buƙatun don daidaiton sutura ba su da tsauri musamman, tasirin yana ƙarami.

2) Kaurin sutura:

A) Electroplating tinning: Kauri mai rufi yana da ɗan ƙaramin bakin ciki, gabaɗaya tsakanin ƴan microns da dubun microns, kuma ana iya sarrafa shi daidai gwargwadon buƙatu.

B) Hot-tsoma tinning: The shafi kauri ne yawanci thicker, kullum tsakanin dubun microns da daruruwan microns, wanda zai iya samar da mafi kyau lalata juriya da kuma sa juriya gatagulla tube, amma maiyuwa bazai dace da wasu aikace-aikace tare da tsauraran hani akan kauri ba.

III. Ingantaccen samarwa

1) Electroplating tin plating: Tsarin samarwa yana da rikitarwa, yana buƙatar matakai da yawa kamar pre-jiyya, electroplating, da kuma bayan jiyya. Saurin samarwa yana da ɗan jinkiri kuma bai dace da babban sikelin da samar da inganci ba. Koyaya, don wasu ƙananan-tsari da buƙatun samarwa na musamman, plating tin electroplating yana da ingantaccen daidaitawa.

2) Hot-tsoma tin plating: The samar da tsari ne in mun gwada da sauki. Ana iya kammala aikin tin ta hanyar nutsewa datagulla tsiria cikin ruwan kwano. Saurin samar da sauri yana da sauri kuma yana iya biyan buƙatun samar da manyan ayyuka.

IV. Ƙarfin haɗin gwiwa:

1) Electroplating tin plating: The bonding ƙarfi tsakanin shafi datagulla tsirisubstrate yana da ƙarfi. Wannan shi ne saboda ion ion ɗin suna haifar da haɗin sinadarai tare da atom ɗin da ke saman ɗigon jan ƙarfe a ƙarƙashin aikin wutar lantarki yayin aikin lantarki, wanda ke sa rufin ya yi wahala faɗuwa5.

2) Hot-tsoma tin plating: Ƙarfin haɗin gwiwa yana da kyau, amma a wasu lokuta, saboda hadaddun halayen da ke tsakanin ruwa na tin da farfajiyar.tagulla tsiriyayin aikin sanyawa mai zafi, wasu ƙananan pores ko lahani na iya bayyana, suna shafar ƙarfin haɗin gwiwa. Koyaya, bayan ingantaccen magani, ƙarfin haɗin gwiwa na plating tin mai zafi yana iya biyan buƙatun yawancin aikace-aikacen.

V. Juriya na lalata:

1) Electroplating tinning: Saboda bakin ciki shafi, da lalata juriya ne in mun gwada da rauni. Duk da haka, idan tsarin electroplating ana sarrafa shi da kyau kuma an gudanar da aikin da ya dace bayan jiyya, irin su passivation, da lalata juriya natinned jan karfe tsirikuma za a iya inganta

2) Hot-tsoma tinning: The shafi ne mai kauri, wanda zai iya samar da mafi kyau lalata juriya kariya gatagulla tsiri. A cikin matsanancin yanayi na muhalli, kamar lamuni da iskar gas, fa'idar juriyar lalatawar tsomawa mai zafi.tinned jan karfe tsiriyafi bayyana5.

VI. Farashin

1) Electroplating tinning: The kayan zuba jari ne in mun gwada da kadan, amma saboda hadaddun tsarin samar, shi yana cinye karin wutar lantarki da kuma sinadaran reagents, kuma yana da high bukatun ga samar da muhallin da masu aiki, don haka da samar farashin ne in mun gwada da high.

2) Tinning mai zafi mai zafi: Zuba jarin kayan aiki yana da girma, kuma ana buƙatar gina tanda mai zafi da sauran kayan aiki, amma tsarin samarwa yana da sauƙi kuma amfanin albarkatun ƙasa yana da ɗan ƙaramin ƙarfi, don haka farashin naúrar na iya zama ɗan ƙaranci a cikin manyan samarwa.

Zabar atinned jan karfe tsiridace da yanayin aikace-aikacen ku yana buƙatar cikakken la'akari da abubuwa masu yawa kamar kayan lantarki, kaddarorin inji, juriya na lalata, tsarin samarwa, farashi da kariyar muhalli. Dangane da takamaiman buƙatu, auna fa'idodi da rashin lahani na kowane bangare kuma zaɓi mafi dacewatinned jan karfe tsiridon tabbatar da aiki da ingancin samfurin.

Lokacin aikawa: Satumba-18-2024