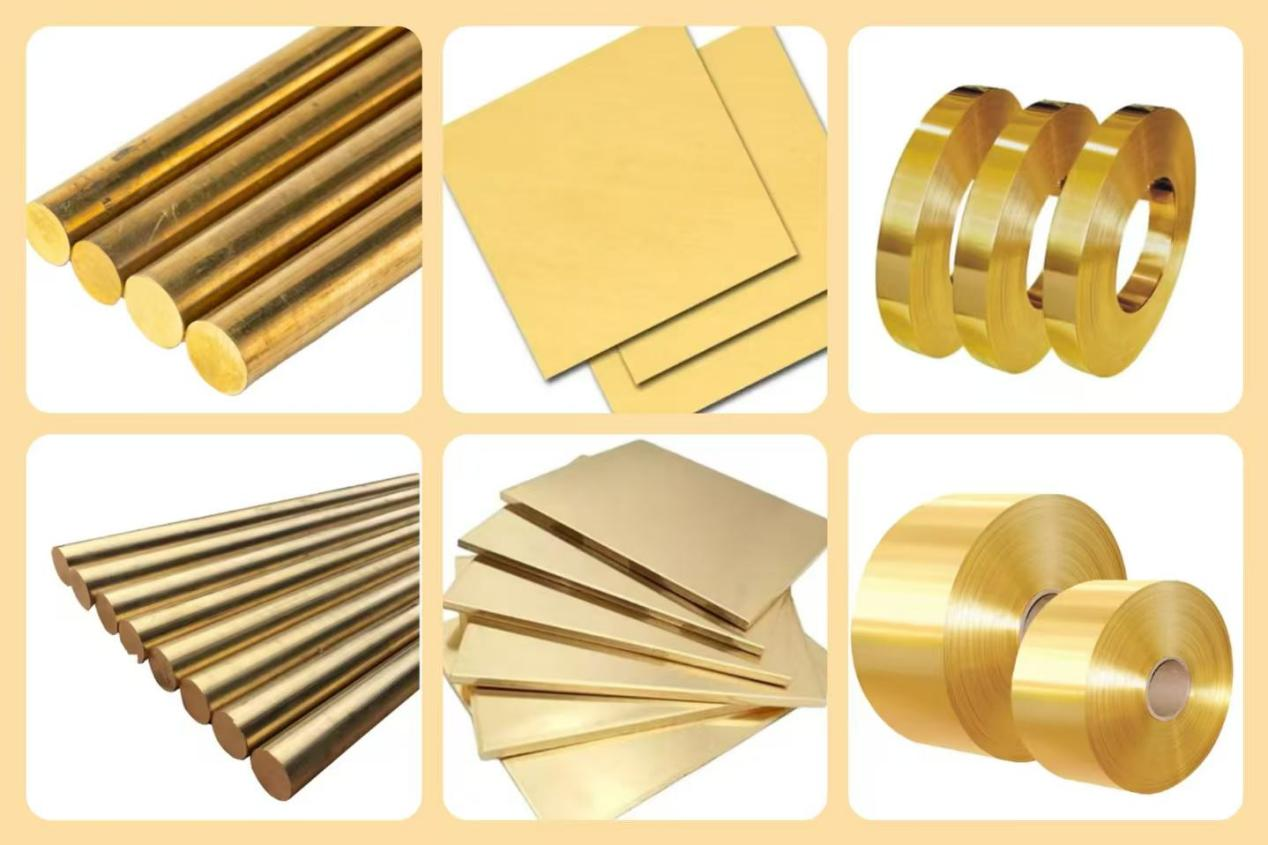

Brasswani gami ne na jan karfe da tutiya, mai kyaun launin rawaya, wanda aka fi sani da brass. Dangane da tsarin sinadaran sa, tagulla ya kasu kashi na jan karfe na yau da kullun da tagulla na musamman.

Tagulla na al'ada shine nau'in nau'in nau'in jan karfe da zinc. Saboda da kyau plasticity, shi ne dace da masana'antu faranti, sanduna, wayoyi, tubes da zurfin-jawo sassa, kamar condensers, zafi bututu, electro-mechanical sassa, da dai sauransu Brass gami da matsakaicin abun ciki na jan karfe na 62% da 59% kuma za a iya jefa, wanda ake kira simintin tagulla.

Tagulla na musamman shine gawa na tushen ƙarfe. Domin samun ƙarfi mafi girma, juriya na lalata da kyakkyawan aikin simintin gyare-gyare, aluminum, silicon, manganese, gubar, tin da sauran karafa ana ƙara su zuwa gariyar jan karfe-zinc don samar da tagulla na musamman. Irin su gubar tagulla, da tagulla, tagulla na aluminum, tagulla silicon, tagulla na manganese, da dai sauransu. Tagulla mai sauƙin aiwatarwa, musamman ma darajar CZ100 tare da ƙimar injin na 121%, kuma an san shi da ingantaccen injin aiki.

Wadannan sune wasu tagulla na musamman na gama gari.

Gubar tagulla

Tagulla na gubar na ɗaya daga cikin tagulla na musamman da aka fi amfani da shi, tare da ingantacciyar injin aiki da juriya. Abubuwan da ke cikin gubar na jan karfen gubar bai wuce 3% ba, kuma ana ƙara ƙaramin adadin Fe, Ni ko Sn sau da yawa.

Tin tagulla

Tin Brass shine tagulla tare da tin wanda aka yi masa ado akan gami da jan karfe-zinc. Tagulla na musamman wanda ya ƙunshi kusan 1% tin. Ƙara ƙaramin gwangwani na iya ƙara ƙarfi da taurin tagulla, hana ɓarna, da haɓaka juriya na lalata tagulla.

Silicon tagulla

Silicon a cikin tagulla na silicon na iya haɓaka kaddarorin inji, juriya da juriya na jan ƙarfe. Silicon brass ana amfani da shi ne don kera sassan ruwa da sassan injinan sinadarai.

Manganese tagulla

Manganese jan karfe ne juriya gami da jan karfe da manganese a matsayin babban aka gyara. Yana samar da daidaitattun resistors, shunts da abubuwan juriya a cikin kayan aiki da mita.

Lokacin aikawa: Maris-31-2025